In-line Inspection - Baseline Survey

Geometric deviations of pipe bore are physical defects which have a serious impact on the pipeline safe operations and its lifetime.

Dents affect the safe operation of a pipeline as they affect the flow of the transported medium and tend to create spot-like formations of sedimentation, turbulence, erosion, corrosion, and hydrates.

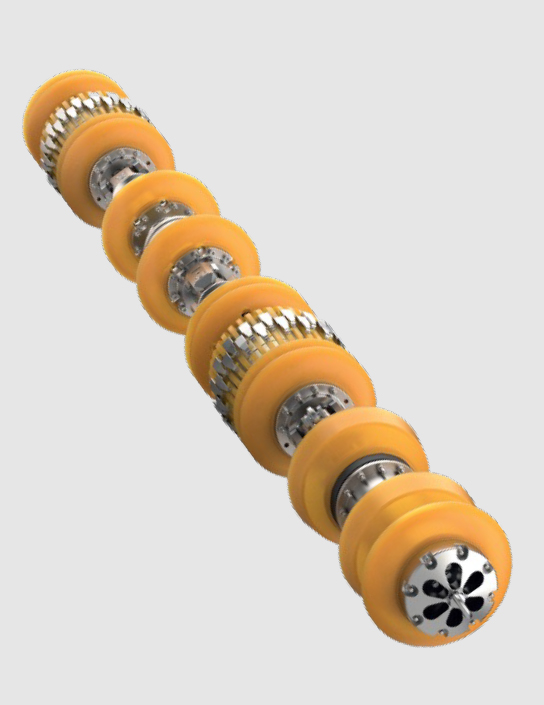

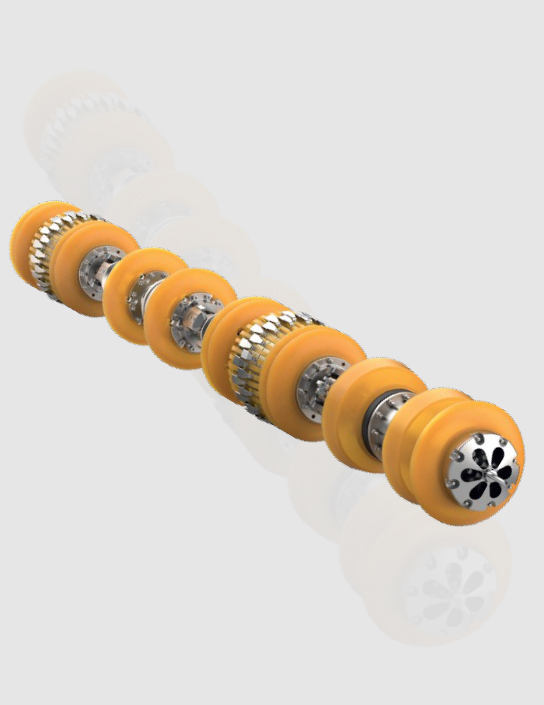

Geometrical / Caliper Survey

Magnetic Flux Leakage (MFL)

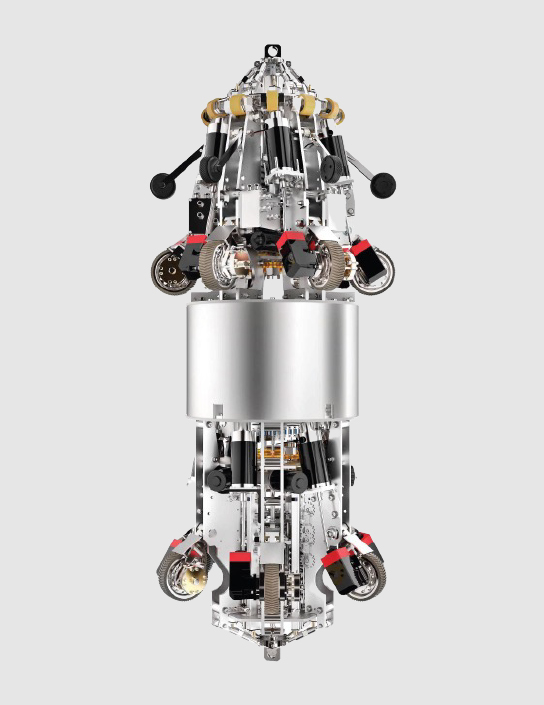

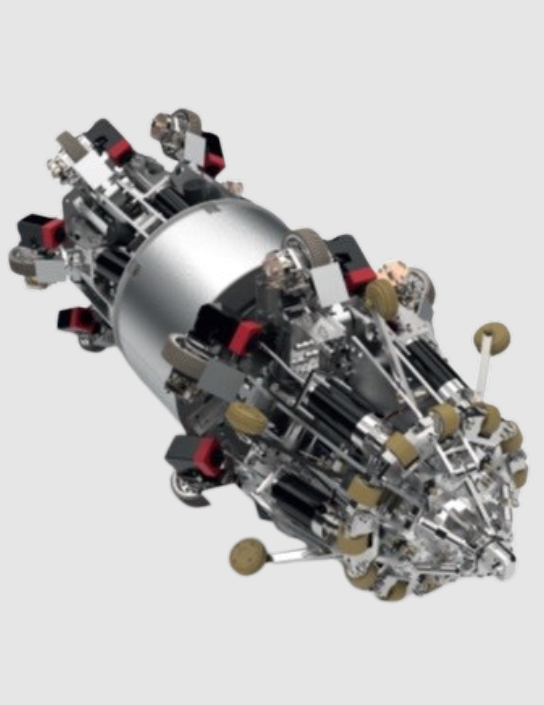

Self-Propelling Tool (SPT)

Caliper-Geometrical Survey

Geometric deviations of pipe bore are physical defects which have a serious impact on the pipeline safe operations and its lifetime.

Dents affect the safe operation of a pipeline as they affect the flow of the transported medium and tend to create spot-like formations of sedimentation, turbulence, erosion, corrosion, and hydrates.

Magnetic Flux Leakage (MFL)

Girth welds, valves, tees, offtakes

Diameters changes

Bends

Ovalities

Dents

Wrinkles

Cable - Free Self - Propelling Tools (SPT)

SPT Tools as Solution

No product or low flow

No launcher or receiver trap

Risers

Diameters between 6” and 56”

Length from 100 m to 100 km

Development and production of ILI tools such as Caliper with navigation unit, MFL, UT, EMAT and cable free self – propelling tools.

LET'S GET STARTED

Our teams of experts are continuously prepared to provide the most optimal and budget-friendly solution that aligns seamlessly with your essential needs.